I-Minerals Moose Creek High Potash Feldspar Page 2018 update

The wheel thrown mug pictured above is the standard Alfred recipe porcelain using Moose Creek Feldspar, fired cone 10.

Notice the degree of translucence and the ease of forming even this thin. The yellow color is due to the light bulb.

40 tons of Moose Creek Feldspar ore was bulk bagged at the Wendt Pottery plant in Lewiston Idaho in

preparation for shipment to the North Carolina pilot processing plant. This pilot run will produce 5 tons of ultra high

purity Moose Creek high potash feldspar for the pottery market and allow full scale testing by interested users.

The samples will become available as soon as the pilot run has been returned to Lewiston for packaging.

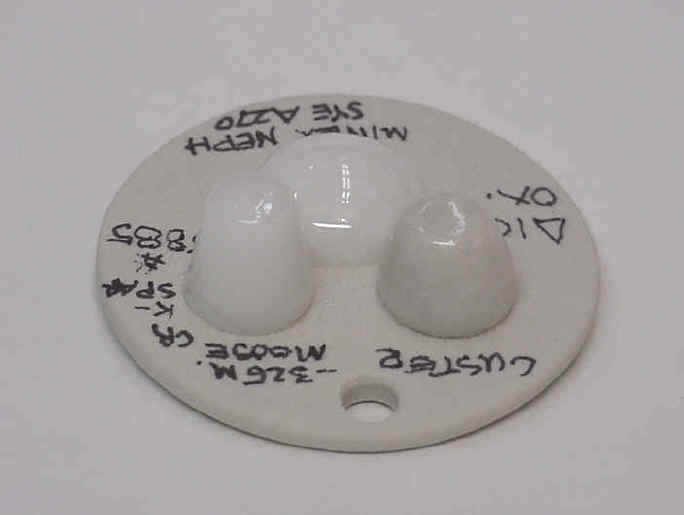

Above are three fusion buttons which are : Moose Creek 325 ( l.), Minex A270 Nepheline Syenite ( c.) , Custer ( r.).

Visually the Moose creek is as white and clean as the Nepheline Syenite, fully fused but more viscous so that it would

offer a stiffer, more slump resistant glass for the production of porcelain.

Bulk Chemistry:

SiO2 Al2O3 Fe2O3 MgO CaO Na2O K2O TiO2

66.46 17.94 0.04 0.03 0.23 1.45 12.04 0.01

The LOI was 0.7 with the balance of the minerals present in trace amounts

Source: Acme Analytical Labs

Above is the 40 ton pile slated to be loaded into the bulk bags for transport and above is the bagging setup in use.

Here is the 40 ton pile now half in the bulk bags and nearly ready for shipment to be processed in North Carolina..

Sadly, the Moose Creek Feldspar project is not going to happen anytime soon.